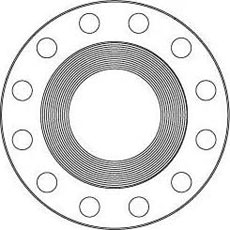

I-Flange Face Qeda

Ukuqedwa kobuso be-Flange

Ikhodi ye-ASME B16.5 idinga ukuthi ubuso be-flange (ubuso obuphakanyisiwe kanye nobuso obuyisicaba) bube namahholo athile ukuze kuqinisekiswe ukuthi le ndawo ihambisana ne-gasket futhi inikeze uphawu lwekhwalithi ephezulu.

Ukuqeda okumise okwesihla, okungaba ku-concentric noma ku-spiral, kuyadingeka ngama-grooves angu-30 kuya kwangu-55 iyintshi ngayinye kanye nomphumela wokuhwashazela phakathi kuka-125 no-500 amayintshi amancane. Lokhu kuvumela amamaki ahlukahlukene okuqedwa komhlaba ukuba atholakale ngabakhi be-flange endaweni yokuxhumana ye-gasket yama-flange ensimbi.

Isithombe sibonisa isiphetho esihlotshisiwe kubuso obuphakanyisiwe.

Ama-Surface asetshenziswa kakhulu

Isitokwe siphelile

Okusetshenziswa kakhulu kunoma yikuphi ukuqedwa kwe-flange, ngoba empeleni, kufanelekile kuzo zonke izimo zesevisi ezijwayelekile. Ngaphansi kokucindezelwa, ubuso obuthambile obuvela ku-gasket buzoshumeka kulokhu kuqedwa, okusiza ukudala uphawu, futhi izinga eliphezulu lokungqubuzana likhiqizwa phakathi kwezindawo zokukhwelana.

Ukuqedwa kwalawa ma-flange kukhiqizwa ithuluzi elinekhala eliyindilinga elingu-1.6 mm ngenani lokuphakelayo elingu-0.8 mm ngokuphenduka ngakunye kufika ku-intshi engu-12. Kumasayizi angu-14 intshi nangaphezulu, isiphetho senziwa ngethuluzi elinekhala eliyindilinga elingu-3.2 mm ekuphakeleni okungu-1.2 mm ukuphenduka ngakunye.

I-Spiral Serrated

Lokhu kuphinde kube i-spiral groove eqhubekayo noma yephonographic, kodwa ihlukile ekuqedeni kwesitoko ngokuthi inkaba ngokuvamile ikhiqizwa kusetshenziswa ithuluzi elingu-90-° elidala i-geometry ethi “V” ene-angle engu-45° serration.

I-Concentric Serrated

Njengoba igama liphakamisa, lesi siphetho sakhiwe ngama-grooves aqondile. Kusetshenziswa ithuluzi elingu-90° futhi ama-serration ahlukaniswe ngokulinganayo ebusweni.

I-Smooth Finish

Lesi siphetho asibonisi izimpawu zamathuluzi ezibonakalayo. Lezi ziphetho zivame ukusetshenziselwa ama-gaskets anezinsimbi ezibhekene nensimbi njengamabhantshi aphindwe kabili, insimbi eyisicaba kanye nensimbi eboshiwe. Izindawo ezibushelelezi zihlangana ukuze zenze uphawu futhi zincike ekucaba kobuso obuphikisanayo ukuze kufakwe uphawu. Lokhu ngokuvamile kufezwa ngokuba nendawo ethinta i-gasket eyakhiwe nge-spiral groove eqhubekayo (ngezinye izikhathi ebizwa ngokuthi iphonographic) ekhiqizwe ithuluzi lekhala eliyindingilizi elingu-0.8 mm ngesilinganiso sokuphakela esingu-0.3 mm inguquko ngayinye enobubanzi obungu-0.05 mm. Lokhu kuzoholela ekuqineni phakathi kuka-Ra 3.2 no-6.3 micrometers (125 - 250 intshi encane).

Ukuphawula koMbhali...

QEDA OKUBUTHELE

Ingabe ilungele i-spiral gasket kanye ne-non metallic gasket?

Lolu hlobo luni lwesicelo?

Imibuzo engenhla ivame ukubuzwa. Ngizama ukunikeza impendulo efanele.

Amaphethelo abushelelezi ajwayeleke kakhulu kumfutho ophansi kanye/noma amapayipi amakhulu odayamitha futhi ahloselwe ukusetshenziswa nensimbi eqinile noma amanxeba okupholisa amanxeba.

Ukuqedwa okubushelelezi kuvame ukutholakala emishinini noma emajoyini ane-flanged ngaphandle kwama-flange amapayipi. Uma usebenza ngokuqedwa okubushelelezi, kubalulekile ukucabangela ukusebenzisa i-gasket encane ukuze unciphise imiphumela ye-creep and cold flow. Nokho, kufanele kuqashelwe ukuthi kokubili i-gasket ezacile kanye nesiphetho esibushelelezi, ngokwazo, kudinga amandla okucindezela aphezulu (okungukuthi i-bolt torque) ukuze kufinyelelwe uphawu.

Kungenzeka ukuthi uwabonile lawa mazwana:

Ukucutshungulwa kobuso be-gasket be-flanges kuze kube sekugcineni okubushelelezi kwe-Ra = 3.2 - 6.3 micrometer

(= 125 – 250 ama-microinchesI-AARH)

I-AARHimele i-Arithmetic Average Roughness Height. Isetshenziselwa ukukala ubulukhuni (kunabushelelezi) bezindawo. 125I-AARHkusho ukuthi ama-intshi angu-125 micro kuzoba ukuphakama okumaphakathi kokukhuphuka nokwehla kwendawo.

63 I-AARHkucaciswe Amalunga Ohlobo Lwendandatho.

125-250I-AARH(kubizwa ngokuthi ukuphela okubushelelezi) kucaciswe kuma-Spiral Wound Gaskets.

250-500I-AARH(kubizwa ngokuthi i-stock finish) icaciswa kuma-gaskets athambile afana ne-NON Asbestos, amashidi e-Graphite, ama-Elastomers njll. Uma sisebenzisa isiphetho esibushelelezi kuma-gaskets athambile ngokwanele "umphumela wokuluma" ngeke ube khona futhi ngenxa yalokho ilunga lingase livuze.

Ngezinye izikhathiI-AARHubizwa futhi ngokuthiRaokusho ukuthi i-Roughness Average futhi isho okufanayo.

Isikhathi sokuthumela: Jul-06-2020