Flange ntsej muag tiav

Flange ntsej muag tiav

ASME B16.5 code yuav tsum kom lub ntsej muag flange (nce lub ntsej muag thiab lub ntsej muag tiaj tus) muaj ib qho kev ntxhib los mos los xyuas kom meej tias qhov chaw no sib haum nrog lub gasket thiab muab lub foob zoo.

Lub serrated tiav, yog concentric los yog kauv, yuav tsum tau nrog 30 mus rau 55 grooves ib nti thiab ib tug resultant roughness ntawm 125 thiab 500 micro inches. Qhov no tso cai rau ntau qib ntawm qhov chaw tiav kom muaj los ntawm flange manufactures rau lub gasket tiv tauj nto ntawm hlau flanges.

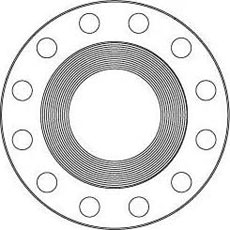

Daim duab qhia tau hais tias serrated tiav ntawm lub ntsej muag Raised.

Qhov feem ntau siv Surfaces

Tshuag tiav

Kev siv dav tshaj plaws ntawm txhua qhov flange nto tiav, vim tias siv tau, tsim nyog rau txhua qhov kev pabcuam zoo tib yam. Nyob rau hauv compression, lub ntsej muag muag los ntawm lub gasket yuav embed rau hauv no tiav, uas yuav pab tsim ib lub foob, thiab ib theem siab ntawm kev sib txhuam yog generated ntawm cov mating nto.

Qhov kawg rau cov flanges no yog tsim los ntawm 1.6 hli vojvoog puag ncig-nosed cuab tam ntawm tus nqi pub ntawm 0.8 hli ib kiv puag ncig mus txog 12 nti. Rau qhov ntau thiab tsawg 14 nti thiab loj dua, qhov tiav yog ua nrog 3.2 hli puag ncig-nosed cuab tam ntawm pub ntawm 1.2 hli ib kiv puag ncig.

Kauv Serrated

Qhov no kuj yog ib qho txuas ntxiv lossis phonographic kauv zawj, tab sis nws txawv ntawm cov khoom tiav hauv qhov zawj feem ntau yog tsim los siv 90-° cuab yeej uas tsim ib qho "V" geometry nrog 45 ° angled serration.

Concentric Serrated

Raws li lub npe qhia, qhov ua tiav no yog tsim los ntawm concentric grooves. Ib lub cuab yeej 90 ° yog siv thiab cov serrations yog sib npaug sib npaug ntawm lub ntsej muag.

Ua kom tiav

Qhov kev ua tiav no qhia tsis pom cov cuab yeej pom pom tseeb. Cov kev ua tiav no feem ntau yog siv rau gaskets nrog cov hlau tig xws li ob lub tsho, cov hlau tiaj tus thiab cov hlau corrugated. Cov npoo du ua ke los tsim ib lub foob thiab nyob ntawm qhov flatness ntawm lub ntsej muag tawm tsam kom ua rau lub foob. Qhov no feem ntau yog ua tiav los ntawm qhov muaj qhov sib cuag ntawm qhov chaw uas tsim los ntawm kev txuas ntxiv (qee zaum hu ua phonographic) kauv zawj tsim los ntawm 0.8 hli vojvoog puag ncig-nosed cuab yeej ntawm tus nqi pub ntawm 0.3 hli rau ib lub kiv puag ncig nrog qhov tob ntawm 0.05 hli. Qhov no yuav ua rau lub roughness ntawm Ra 3.2 thiab 6.3 micrometers (125 - 250 micro nti).

Remark(s) of the Author…

SMOOTH FINISH

Puas yog nws haum rau kauv gasket thiab tsis yog xim hlau gasket?

Rau hom kev thov no yog hom twg?

Cov lus nug saum toj no feem ntau nug. Kuv sim muab lus teb kom raug.

Smooth finish flanges muaj ntau dua rau qhov tsis tshua muaj siab thiab / lossis loj txoj kab uas hla thiab feem ntau yog npaj rau siv nrog cov khoom hlau lossis kauv qhov txhab gaskets.

Smooth finishes feem ntau pom nyob rau hauv machinery los yog flanged pob qij txha uas tsis yog cov yeeb nkab flanges. Thaum ua haujlwm nrog kev ua tiav zoo, nws yog ib qho tseem ceeb uas yuav tsum xav txog kev siv lub tshuab ua kom nyias nyias kom txo tau qhov cuam tshuam ntawm kev nkag thiab dej txias. Nws yuav tsum raug sau tseg, txawm li cas los xij, tias ob qho tib si nyias nyias thiab qhov ua tiav, nyob rau hauv thiab ntawm lawv tus kheej, yuav tsum muaj zog compressive ntau dua (piv txwv li bolt torque) kom ua tiav lub foob.

Tej zaum koj yuav tau pom cov lus no:

Machining ntawm gasket ntsej muag ntawm flanges mus rau ib tug du tiav ntawm Ra = 3.2 - 6.3 micrometer

(= 125 - 250 microinchesAARH)

AARHsawv cev rau Arithmetic Average Roughness Height. Nws yog siv los ntsuas qhov roughness (es smoothness) ntawm qhov chaw. 125AARHtxhais tau tias 125 micro inches yuav yog qhov nruab nrab qhov siab ntawm qhov nce thiab nqis ntawm qhov chaw.

63 AARHyog teev rau Ring Type Joints.

125-250 : kuvAARH(nws yog hu ua du tiav) yog teev rau Kauv Kab Mob Gaskets.

250-500AARH(nws yog hu ua cov khoom tiav) tau teev tseg rau cov khoom muag muag xws li NON Asbestos, Graphite nplooj, Elastomers thiab lwm yam. Yog tias peb siv cov khoom tiav rau cov khoom muag muag txaus "tom qab" yuav tsis tshwm sim thiab vim li no qhov sib koom ua ke tuaj yeem tsim tawm.

Qee zaumAARHkuj hu uaRauas sawv cev rau Roughness Average thiab txhais tau tias tib yam.

Post lub sij hawm: Jul-06-2020